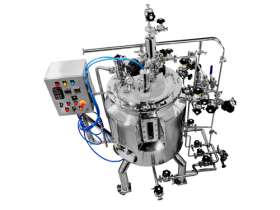

Aryan Engineers is a top-rated provider of aseptic mixing vessel required for chemical, pharmaceutical and cosmetic industries. We supply a comprehensive range of injectable mixing vessel for your customized requirements. We ensure timely delivery of all orders, and thus we have become the favourite supplier of some of the leading manufacturing units in diverse industries. We have a high demand for mixing vessel for injectable product for sanitary, industrial and general applications. We use stainless steel and modern alloys to build process vessel for injectable products. Hence, these products are highly efficient to provide, integrate and store highly vulnerable and harmful products for a long time.

ASPETIC MIXING VESSEL

ASPETIC MIXING VESSEL

Create a Sterile Environment with our Premium Aseptic Mixing Vessel

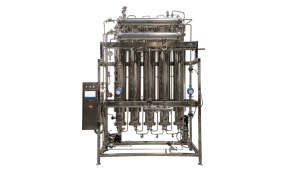

Large Volume Parenterals Manufacturing Tank

Our LVP manufacturing tank is designed optimizing the latest technology. These products are suitable for pharmaceutical and diverse industrial uses. Our SVP manufacturing tank meets the highest criteria of sterility in the required specifications. We manufacture these products fully adhering to the various quality standards set by WHO, USFDA and MHRA. We also strictly follow the guidelines provided by ASME in creating all our products.

We are a customer-oriented service of Aseptic process vessel production and supply to our clients in India and at the international levels. We are a recognized mixing tank manufacturer. The mixing tanks we supply are excellent in mixing various components for production in your industry. The mixing tank comes with a stainless steel body, and it is one of our most sold products ever. You are welcome to Contact us so that we can provide you with the salient features of all our products.

Applicaon

- Sterile Soluon

- PFS Soluon

- Vial / Ampoules

- Oral Liquid Products

- I V Fluids

- Cosmecs

- Vaccines

Salient Features

- Bottom Magnetic Mixer

- Bottom Entry Mixing System with Double Mechanical Seals

- Top Entry Mixing System with Double Mechanical Seals

- Crevices and dead leg free contact surfaces,

- Electropolished from inside <0.5 Ra finish

- 100% Drainability

- Completely suitable for CIP& SIP

- Aspetic Sampling facility

- Flush mounted Tank Boom Diaphragm Valve

- Sterile Micron Filtraon System

- Food Grade Gaskets

- Process Automaon with Piping and Transferring Systems